Imagine you’re working hard to beat the clock and meet your project’s deadlines. Suddenly, lights begin to flicker, machinery stalls, and your team’s progress comes to a screeching halt. So, how could all these setbacks have been avoided? The answer is simple, learn how to identify the signs that it’s time for temporary power equipment replacement. Knowing when to swap out old equipment for new pieces of temporary power gear can help you prevent breakdowns and keep your project’s progress on track.

While all our equipment is made with durable materials and boasts top ratings such as NEMA, CSA, UL, and RoHS approvals, all equipment eventually falls victim to the test of time. Temporary power equipment, such as transfer switches, are responsible for distributing all the electricity necessary to bring your lights, tools, and machinery to life. Failing to recognize the signs that your portable power equipment is at the end of its life can have serious consequences.

Alongside pausing progress, worn-out equipment can pose a serious threat to the safety of your team. When left unaddressed, damaged equipment can cause sparks, arcing, shocks, and deadly electrical fires. Thankfully, our team of experts are here to share our top three warning signs that your temporary power equipment needs to be replaced. This way, you can take proactive steps to make sure that your power system is always in pristine condition.

Burning Odors

If you ever smell a burning odor coming from your temporary power system, this is a warning alarm that something isn’t right! Whether you smell a faint scent or pungent odor, this is a telltale sign of overheating that should not be taken lightly. When equipment becomes overloaded, has internal damage, or is poorly ventilated, excessive heat can build up and eventually lead to an electrical fire.

If you detect a burning smell or the scent of smoke, be sure to shut down your power system immediately. After all components have been de-energized, schedule a visit with a licensed electrician to help you identify which piece of equipment is the root of the problem. Quick intervention and temporary power equipment replacement will prevent further damage and keep you and your team out of harm’s way.

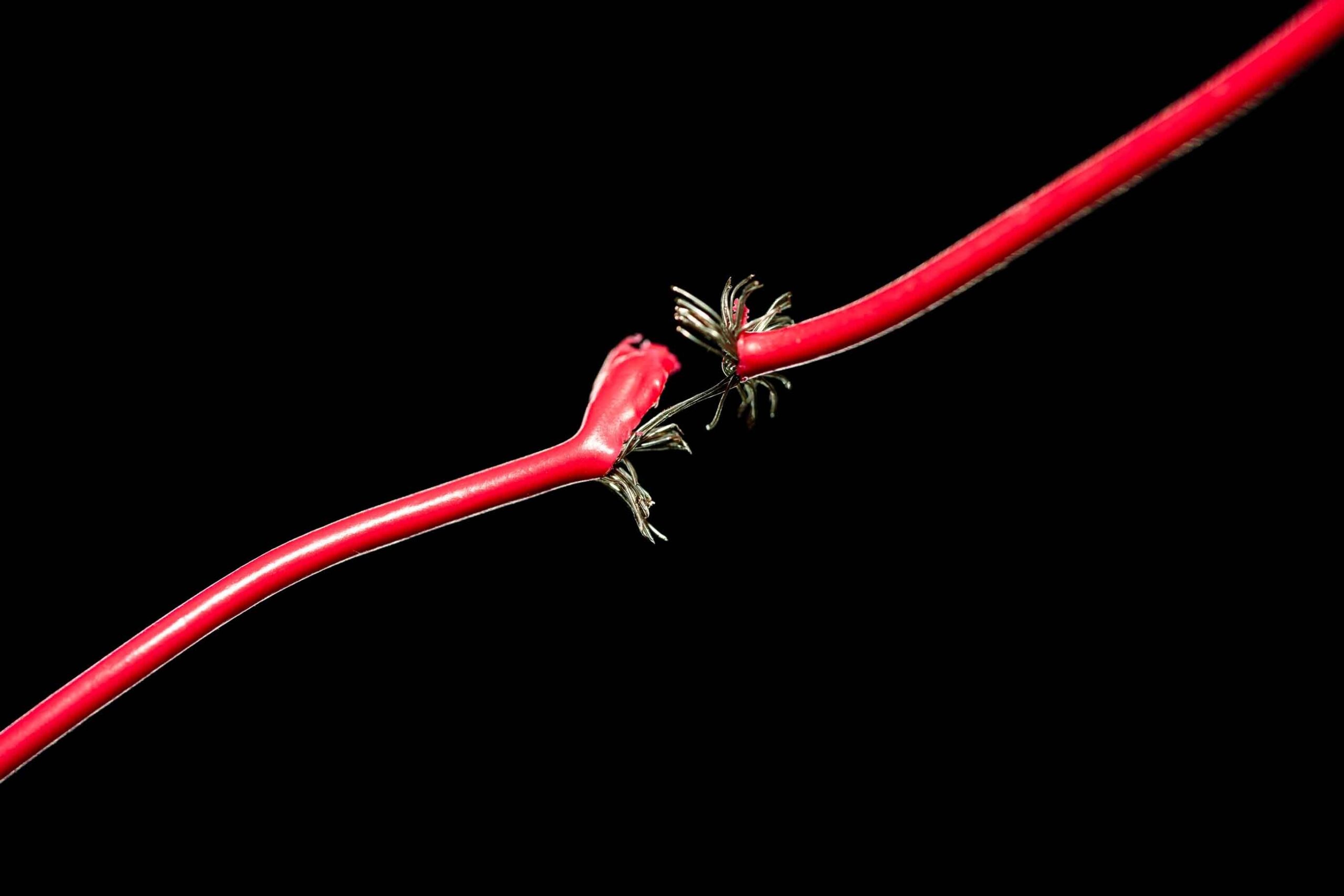

Visible Equipment Damage

If you find cracks, rust, or exposed wires on your emergency power gear, take it as a red flag that your temporary power equipment urgently needs to be replaced. Even though our power solutions are made with crack-resistant Camlocks, corrosion-resistant enclosures, and reinforced cable jackets, all equipment is bound to accumulate damage from repeated use.

The good news is that our team is always here when it’s time for your temporary power equipment replacement. We keep our inventory fully stocked with emergency replacement parts, like our inline and Panel Mount Camlocks, so that you can quickly swap out old components and keep your project’s operations up and running.

We also offer cable assemblies and power distribution units, such as Camlock Connection Boxes and Generator Docking Stations, in a wide array of configurations so that you always have access to what you need. Furthermore, we have stock located on both coasts of the United States so that we can offer you same-day shipping with expedited options for record-breaking lead times!

Dimming Lights and Stalling Machinery

Declining performance is another key indicator that it’s time for your temporary power equipment replacement. Electrical systems don’t become sluggish for no reason. It can be a sign of overloading, buildup, and degrading components. When your emergency power’s performance begins to falter, you’re at risk of dangerous malfunctions and expensive equipment damage.

Remember, when it comes to portable power, kicking the can down the road only leads to larger, more expensive issues later on. As soon as you notice that your equipment isn’t performing quite the way it used to, be sure to act fast. Reach out to a local electrician and ask them to troubleshoot the issue. During their inspection, they can determine what equipment is at fault and should be replaced.

By looking for the warning signs listed in this article and tackling issues head-on, you can stay ahead of the curve and avoid unnecessary delays. We hope that you have enjoyed this article and feel better equipped to keep your temporary power system running at peak condition. If you find yourself in need of new temporary power equipment, please contact us at [email protected] and we’ll be happy to help you refresh your backup power system!